Starting from the desire to solve problems through manufacturing, we at Make Start have expanded the high-precision machining technologies and creative ideas cultivated in the fields of automotive parts and rubber molds into a wide range of areas. From zero-tolerance molds that enable a comfortable car life, to medical devices that protect lives by responding to real on-site needs, to tools that meet the expectations of professionals and players—what all of our businesses share is manufacturing that stays close to the user’s voice and captures the essence of what is truly needed.

With innovation, a sense of playfulness, and care for people at heart, Make Start’s five business domains continue to shape new value for the future.

Rubber has complex physical properties, such as expansion and contraction. Producing high-quality molds that accommodate these characteristics is extremely challenging, and only a limited number of manufacturers worldwide specialize in rubber molds.

Make Start is a team of engineers highly skilled in rubber molding dies. In the field of automotive weatherstrip rubber molds—which require advanced 3D machining—we have built one of the top track records in Japan. Weatherstrips created from our high-function, safe, and user-friendly molds are widely adopted by major domestic automobile manufacturers.

Believing that “even with the latest equipment, people make the final difference,” we have established five overseas bases where we train local engineers, enabling us to deliver Japan-quality products on a global scale. We also demonstrate strong technical capabilities in resin molding dies, providing repair and maintenance services even for molds not produced in-house.

Mold manufacturing is the very origin of Make Start. By continually refining our technologies and expertise, we strive to become a global leader in the field.

There are people who risk their own lives to save the lives of others. In medical settings, healthcare professionals sometimes place themselves in danger to protect their patients. Our first step into the healthcare field began with the awareness of these frontline realities—an awareness held deeply by our CEO, who is himself a practicing physician.

Our first product was TOUCH WRAP, developed during the COVID-19 pandemic as a solution for keyboards that are difficult to disinfect. The device allows users to wrap keyboards with commercially available film and easily replace it as needed.

Next, in collaboration with Teikyo University, we developed FORUshield, a radiation protection panel designed to reduce physicians’ exposure during catheter procedures—especially the exposure risks faced by pregnant female doctors—while maintaining a structure that does not interfere with delicate operations. The product received a patent and also earned an industry–academia collaboration award.

Manufacturing has the power to protect health and save lives. With this belief as our driving force, we will continue to stay close to the needs of the medical field and deliver new value to the healthcare and wellness sectors.

What is demanded today is near–zero tolerance—shaping with precision that delivers truly advanced performance. To meet this need, we drew on the technologies and expertise cultivated through manufacturing molds for automotive parts and created the MUQU golf club. Through precision machining that sculpts solid steel, we achieved artisanal beauty and an extraordinary accuracy measured in units of 0.01 mm.

MUQU is the culmination of master craftsmen who wanted to “create something entirely new with our own technologies,” embracing the pure joy of craftsmanship. The made-to-order option that allows players to select from three types of steel is a concept made possible only by Make Start, a company that deeply understands “living steel.” Because we know that steel behaves like a living material—with its own character—we can offer a club that resonates with each player’s sensibilities.

What began as a bold challenge that shocked the industry has expanded into the development of irons, wedges, putters, and training balls, captivating golfers both in Japan and overseas. With our unique ideas and technologies, we will continue to stand beside players and push the boundaries of what enhances performance.

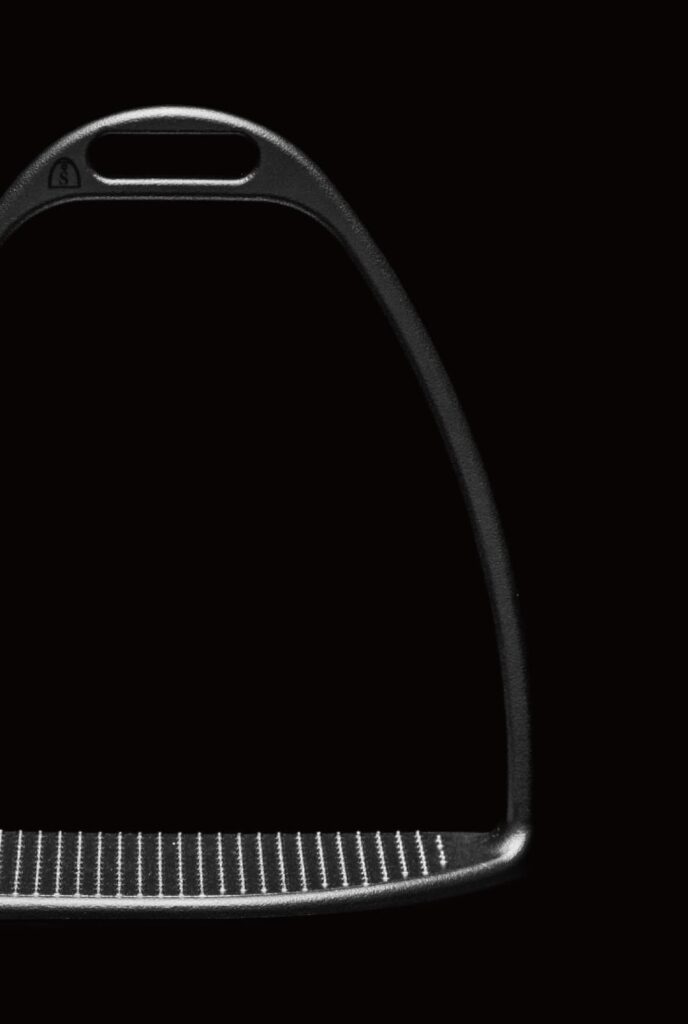

It all began with a single comment from a legendary jockey. We first learned of Yutaka Take’s struggle when he mentioned, “There isn’t a stirrup that fits me—my feet hurt.” A stirrup is an essential tool that affects riding posture, operability, and ultimately a jockey’s safety. Yet at the time, there were no domestic manufacturers; every Japanese jockey relied solely on foreign-made products.

The realization that even Japan’s top jockey faced such difficulties came as a shock. Determined to change this, we set out at Make Start to create Japan’s own stirrup. Using the machining expertise we had cultivated through mold manufacturing, we worked closely with Take, going through repeated prototypes and refinements until we completed ABUMI, the first stirrup made in Japan.

Take used ABUMI in top-level races around the world—including the prestigious Prix de l’Arc de Triomphe—and achieved numerous victories. A co-developed model with jockey Yuga Kawada later joined the lineup, and “Made in Japan” stirrups have since earned high praise internationally. Today, development of the next generation of tack is already underway. With Make Start’s unique sensibilities, we continue to bring fresh innovation to the equestrian world.

Our outdoor products business was born from a simple desire: to solve everyday inconveniences through manufacturing. In recent years, more people have begun enjoying camping, but tasks such as splitting firewood and driving tent pegs require significant strength. Many users—especially women and children—expressed concerns about the difficulty and danger of using tools like hatchets and axes.

This led us to focus on the tagane, a metalworking chisel. Our craftsmen re-engineered its angle specifically for splitting firewood, creating Senpō, a camping wedge that allows users to split wood safely and with minimal force. We also developed Tezuichi, a dedicated hammer that fuses the expertise of swordsmithing, woodworking, and metalworking—a true culmination of craft and industrial technique.

The product brand name, Owari no Ooutsuke, pays homage to Nobunaga Oda, a historical figure from our hometown of Kiyosu City. Known as an “outsuke” (a fool or eccentric) in his youth, Nobunaga defied convention and pursued the essence of things—an attitude that mirrors our own approach to manufacturing.

Moving forward, we will continue blending function and design to expand the joy of outdoor experiences.